In-stock items ordered by 11 AM EST will ship out

the same day. Your order is our priority!

-

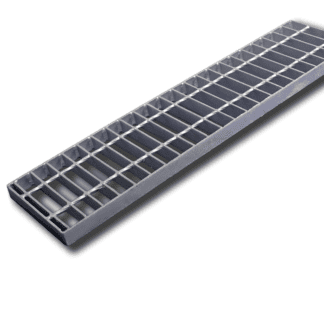

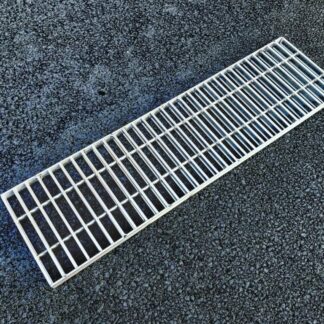

Galvanized Steel Bar Grates (49)

-

Black Steel Bar Grates (8)

-

Aluminum and Stainless Steel Grates (63)

-

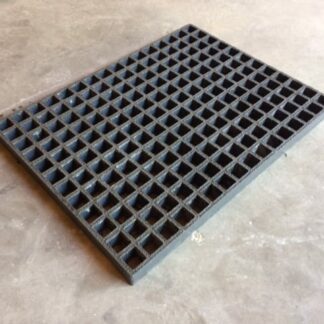

Fiber Glass Grates (32)

-

Slotted Trench Covers (20)

-

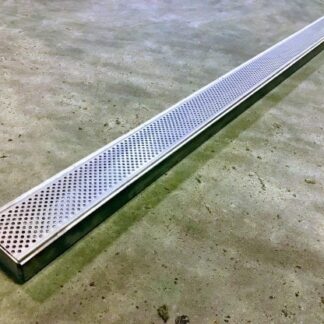

Perforated Metal Trench Covers (8)

-

Solid Covers (6)

-

Angle Iron Embeds with Studs (38)

-

Slotted Pit Covers (22)

-

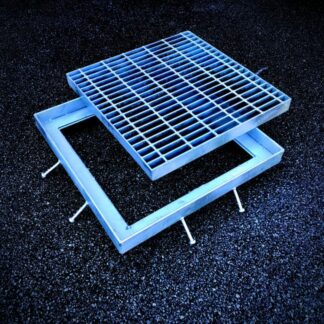

Bar Grating Pit Grates (45)

-

Fiber Glass Pit Grates (10)

-

Sump / Pit Grates with Frames (22)

-

Foam Trench Drain Systems (18)

-

Steel Trench Drain Systems (4)

-

Restaurant and Food Processing (45)

-

Slotted Trench Drains (4)